Laser Micro Drilling

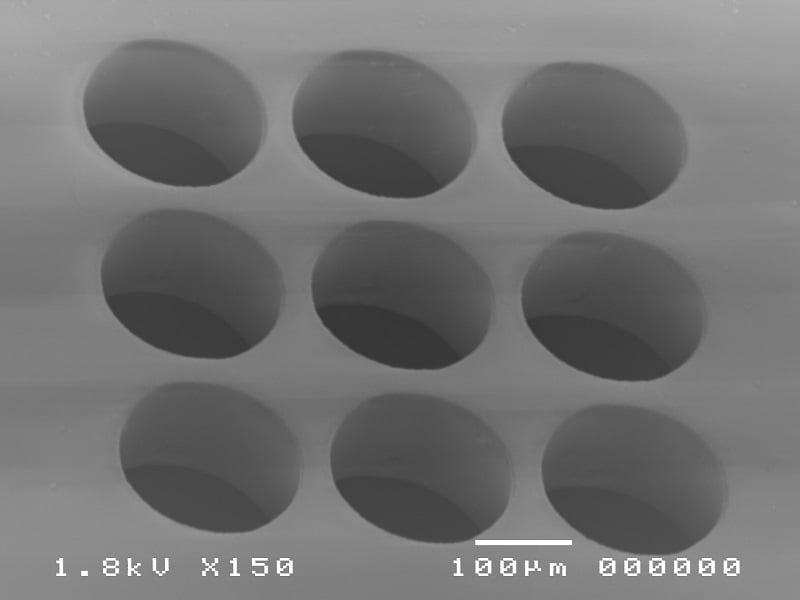

Micro drilling is a laser micromachining process which creates extremely precise micro-scale holes in material. Different hole shapes; round, square, rectangular, oval, etc. can be produced by varying the laser drilling technique.

From standard pinholes in stainless steel discs to complex arrays in semiconductor guide plates, we provide a wide range of drilling services in the production of parts for numerous applications.

In fact, with decades of experience in laser micromachining, we have developed processes and capabilities to machine almost all materials, even hard to machine ceramics and transparent materials in our applications laboratories.

The use of lasers for micro drilling has become widely accepted in a wide variety of industries including the electronics and automotive sectors and applications in displays and energy.

Each application has different needs including the type of hole geometry required as well as the number of holes per part ranging from a single hole to many tens of thousands. Oxford Lasers micromachining services can provide a wide variety of options to meet those needs.

Laser drilling can produce not only circular and rectangular holes, but these holes can be produced with a variety of tapers. In addition, holes can be drilled at angles normal to the surface of the material or if required at very acute angles to the surface.

There are a variety of processing techniques available when undertaking laser drilling. These techniques can result in many hundreds of holes being drilled per second and / or these holes having extremely high quality, where hole after hole, the shape is identical.

Holes can be drilled on parts, where the hole positional accuracy is less than 2 microns.

Oxford Laser have a wide variety of lasers available for laser drilling. These range from ultrafast picosecond and femtosecond lasers through to nanosecond and longer pulsed lasers. This allows us to select not only the best laser pulse length, but also wavelength to suit your particular application.

Read our latest article on femtosecond MHz burst mode laser drilling

Go to ArticleSpecialised Laser Drilling Applications

With decades of laser industry knowledge of techniques and materials, Oxford Lasers has developed specialist skills within high-precision laser drilling.

- CCIT - Precision laser drilling in pharmaceutical packaging to create positive controls in container closure integrity testing

- Guide plate - ultra high precision laser drillring for semiconductor wafer test

- Sample prep - laser drilling of samples for XRM (X-ray microscopy)

- PZT - laser processing of PZT in medical device ultrasound manufacture